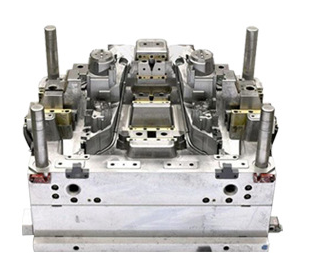

1. Injection Mold It is mainly a type of molding mold that is most commonly used in the production of thermoplastic parts. The processing equipment corresponding to the injection mold is the Injection Molding machine. The plastic is first heated and melted in the bottom heating cylinder of the injection molding machine, and then pushed by the screw or plunger of the injection molding machine, it enters the mold cavity through the injection molding machine nozzle and the mold pouring system. The plastic is cooled and hardened to form, and the product is demolded.

2. Extrusion mold

A type of mold used to shape and produce plastic products with continuous shapes, also known as extrusion molding heads, is widely used for the processing of pipes, bars, monofilaments, plates, thin films, wire and cable coatings, and profiles. 3. High foaming polystyrene molding mold It is a kind of mold that uses expandable polystyrene (beaded material composed of polystyrene and foaming agent) raw materials to form foam plastic packaging materials of various shapes. Its principle is that expandable polystyrene can be steam formed in the mold, including two types of simple manual mold and hydraulic straight through foam Plastic Mold, which are mainly used to produce packaging products for industrial products. The materials used to manufacture this type of mold include cast aluminum, stainless steel, bronze, etc.

4. Blister mold A type of mold that uses plastic plates and sheets as raw materials to form some relatively simple plastic products. Its principle is to use the vacuum opening method or compressed air forming method to deform the plastic plates and sheets fixed on the concave or convex molds and adhere them to the mold cavity under heating and softening to obtain the desired formed products. It is mainly used in the production of some daily necessities, food, and toy packaging products.