The production of Injection Mold construction is the responsibility of mold manufacturers. In order to apply it to the production lines of different manufacturers, each mold has different performance, materials and characteristics to ensure that the plastic molding meets the design requirements. The mold itself has a complex structure and different module composition. The processing method is relatively complex and the relative precision is high. It needs to use a variety of modern high-precision processing equipment, such as CNC machining centers, milling machines and cutting machines, Wire cutting, laser cutting, heat treatment, etc.

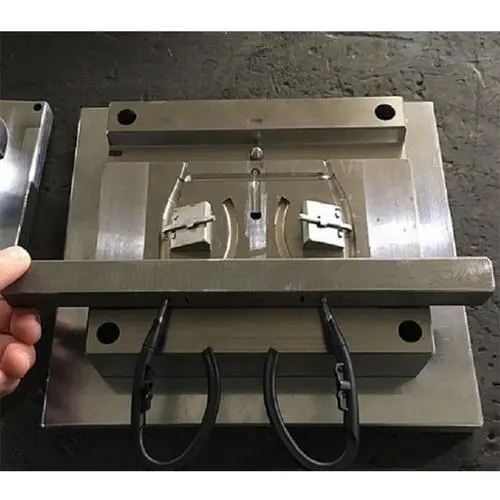

If you want to know how the Injection mold construction is produced, you must first know the components of the Injection mold construction, including the dead angle treatment structure, (oil cylinder, bevel top device, slider), auxiliary accessories (KO hole, lifting eye hole), auxiliary systems (exhaust system, pouring system, cooling system, ejection system), auxiliary parts (orifice bushing, ejection plate guide post guide sleeve, support column, ejector pin, garbage, grab pin), mold core, Mold frame, these are important links in the production of Injection mold construction.

Before the production of Injection mold construction, it is necessary to use computer graphics software to make the mold plan and 3D drawing, evaluate the drawings, and then use wood and resin materials to make the prototype. This small batch of Injection mold construction is used to verify the technology. After receiving the test report through verification, alloy materials will be used for processing and manufacturing. During the verification process, if the accuracy does not meet the standard, Or if there are process issues, they can be corrected in a timely manner. Today's Injection Molding models often need to cooperate with electrical control to meet higher requirements for automated production, higher use intensity, and higher requirements for mold rigidity. The use of various hard and ductile alloys has become the mainstream, such as zinc alloy, copper base alloy, aluminum alloy, and high carbon steel, which have become indispensable basic materials for Injection mold construction production. In order to process these materials and achieve higher precision requirements, The natural need to use automation equipment has brought about a demand for upgrading and upgrading to mold manufacturers. Injection mold construction production should choose the right manufacturer. Although China needs a large number of Injection mold construction every year, there are obviously a few qualified manufacturers. Kaidi brand focuses on the design and production of Injection mold construction, leaving a good reputation in the industry, cultivating professional skills team, and exploring with the demander in the front line all the year round. Kaisijin brand has perfect mold manufacturing quality control management, ensuring the quality of Injection mold construction.