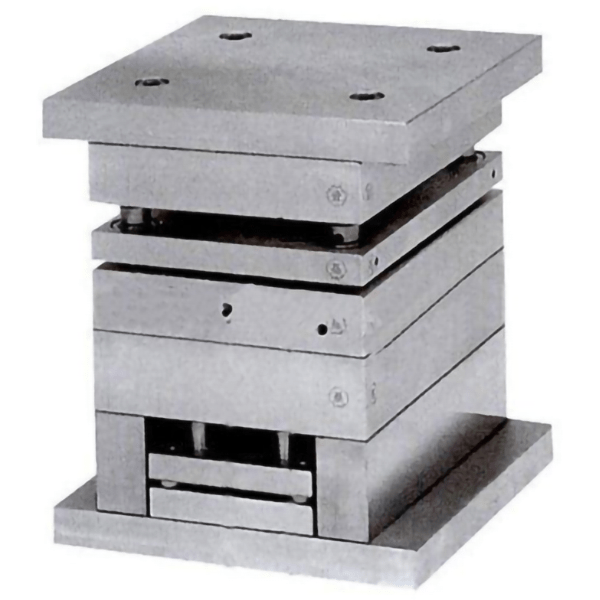

The characteristics of Mold processing are as follows: (1) The machining accuracy requirement is high, and a mold is generally composed of a concave mold, a convex mold, and a mold base, and some may also be multi piece assembled modules. Therefore, the combination of upper and lower molds, the combination of inserts and cavities, and the assembly between modules all require high machining accuracy. The dimensional accuracy of precision molds often reaches μ M-level. (2) The shape and surface of some products, such as automotive panels, aircraft parts, toys, and household appliances, are complex. The surface of their shape is composed of multiple curved surfaces, so the mold cavity surface is very complex. Some surfaces must be processed using mathematical calculations. (3) Small batch size means that the production of molds is not mass production, and in many cases, only one batch is produced. (4) There are multiple processes involved in mold processing, including milling, boring, drilling, reaming, and threading. (5) Repetitive production and the use of molds have a lifespan. When a mold exceeds its lifespan, it needs to be replaced with a new mold, so the production of the mold often has repeatability. (6) Copying processing, sometimes in mold production, there are no drawings or data, and it is necessary to perform copying processing based on the actual object. This requires high imitation accuracy and no deformation.

(7) The die material is of good quality and high hardness. The main material of the die is mostly alloy steel, especially the die with long service life, which is often made of ledeburite steel such as Crl2 and CrWMn. This type of steel has strict requirements from rough forging, processing to heat treatment. Therefore, the compilation of processing technology cannot be ignored, and heat treatment deformation is also a problem that needs to be taken seriously in processing.

Dongguan Kaisijin Intelligent Technology Co., Ltd. is an enterprise specializing in large-scale hardware mold processing, mainly engaged in vacuum heat treatment, mold machining, mold steel and hardware accessories, precision mechanical component manufacturing, and semiconductor automation equipment guide rail module processing. The company has many years of precision machining experience and strong technical strength, specializing in the manufacturing and processing of large precision equipment. We can deeply process according to customer drawings. If you provide drawings, we are your production workshop.