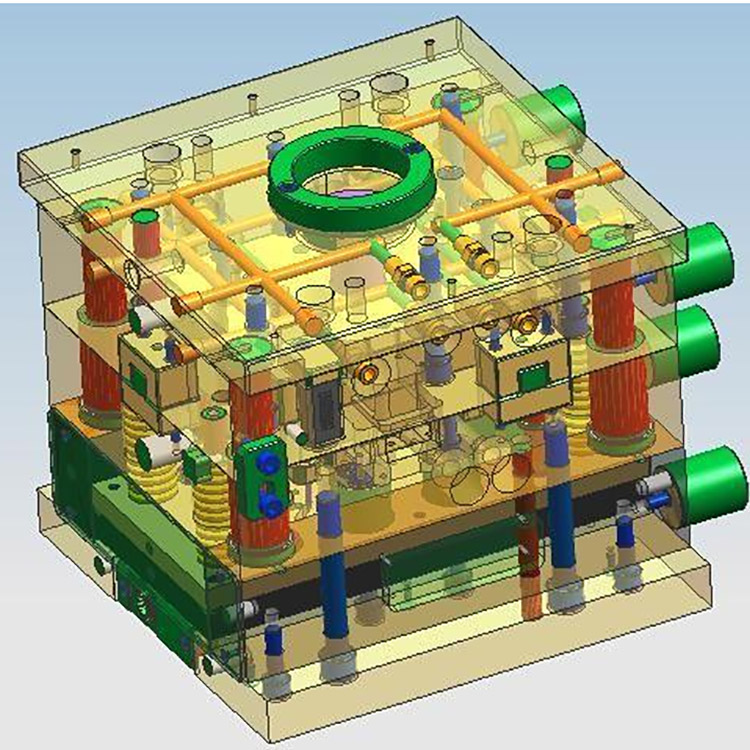

There are many reasons that affect the cycle cycle of plastic molds, among which three are directly related to the Mold cycle. 1. Reasons for the mold itself: including a: cooling system, b: Injection Molding system, c: mold guidance system, d: ejection system, etc., can all affect the mold cycle cycle.

a: The cooling system requires uniform cooling, and the mold needs to be fully cooled b: The injection system requires uniform injection molding, and it is necessary to reduce injection molding obstacles, such as flow channel obstacles. c: The guidance system requires the guide pillar to be smooth and unobstructed with other guides. It is best for the ejection system to achieve synchronous ejection after mold opening without any ejection noise.

2. Machine reason: Insufficient pre molding speed of the machine will directly affect the mold cycle. Pre molding is related to screw speed. Injection molding speed, such as injection pressure, screw pushing speed, mold opening and closing speed, and ejection of the injection molding machine, will all affect the mold cycle cycle. 3. Other reasons affecting the mold cycle; a. Plastic flow rate, b, injection molding process, c, injection molding environment, such as cooling water temperature, climate factors.