Introduction to Injection Molding - Other Auxiliary Systems

Transport plate: A small plate that connects the male and female molds during the transportation and lifting process of the Mold without separating the male and female molds. Nameplate: Identify mold ownership, mold molding parts, mold manufacturing time, mold factory information, etc.

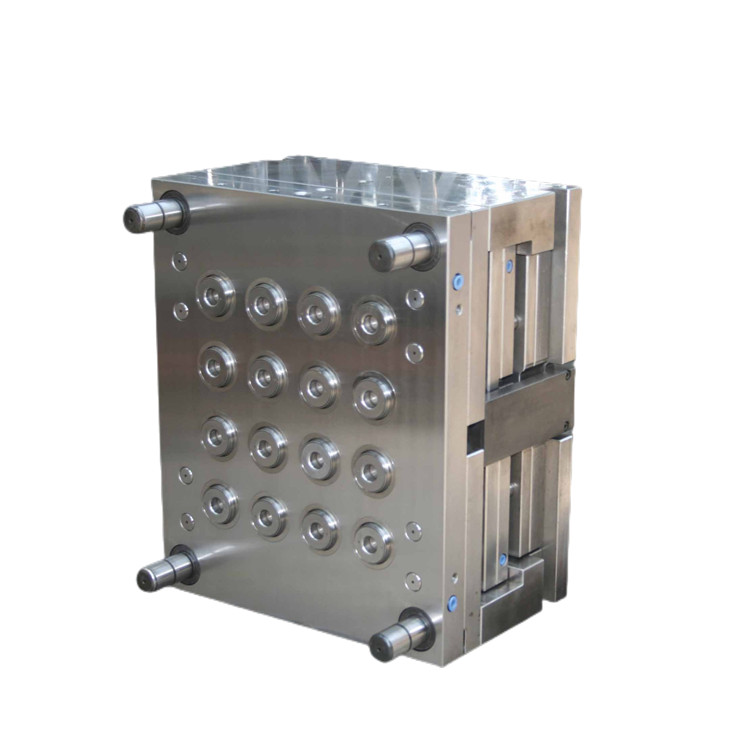

Lifting hole: A screw hole machined on the template for lifting the mold with a lifting device when erecting the mold. Each single template must have a mold lifting hole.

Pry mold pit: Generally, the gap at the four corners of the template is mainly used to facilitate mold disassembly and assembly, especially for male templates. As the mold comes down from the molding machine, the mold cavity pressure will be less than the external atmospheric pressure, and with plastic adhesive, the mold must be pried open. Microswitch: A confirmation switch that confirms that the ejector pin plate returns to position after mold opening is confirmed. It can also be used in the oil cylinder travel switch. Dust shield: The movement of the ejector plate requires a certain amount of space. This part of the mold is open, and it is easy to fall into other things, such as wrenches, material heads, etc., causing the processing mold to jam. At this time, a plate is installed on the upper surface of the mold to shield it, which is called a dust shield. Counter: Shows how many times the mold has been opened and closed